Coation Service

Green Optics (GO) offers a comprehensive range of advanced coating services tailored to meet diverse customer needs. Our state-of-the-art equipment such as E-beam Vacuum Coaters, Sputter Coaters, and Plasma Clean Systems, and expertise ensure that we deliver high-quality optical coatings suitable for various applications.

Key Features of Our Coating Services

-

Customized Coating Designs:

We specialize in developing coating films tailored to meet specific durability requirements and environmental conditions, ensuring optimal performance in any setting. -

Reliability Testing:

All coatings undergo rigorous reliability tests to ensure they meet industry standards and customer expectations. -

Advanced Coating Technology:

Our coating capabilities span from Deep UV to FLIR, accommodating a wide range of wavelengths and applications. -

Large Chamber Capacity:

Our coating chambers can accommodate diameters of up to Ø 3200 mm, allowing for the application of various 2M-grade coatings. -

Precision Measurement:

We provide precise measurement capabilities for wavelengths ranging from 193 nm to 14 µm, ensuring the accuracy and effectiveness of our coatings. -

Scalability:

Our facilities are equipped to handle everything from small sample sizes to mass production, ensuring flexibility to meet customer demands. -

Expert Consultation:

Our skilled coating engineers are available for consultations at any time, helping you discuss specifications and find the best solutions for your coating needs.

At Green Optics, we are committed to providing top-notch coating services that enhance the performance and durability of optical components. With our advanced technology and dedicated team, we ensure that our coatings meet the highest standards of quality and reliability. Whether you require custom solutions or mass production, we are here to assist you every step of the way.

Coating Sectors

|

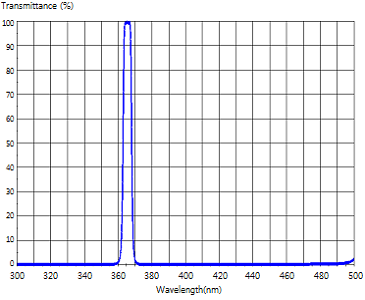

Band Pass Filter

|

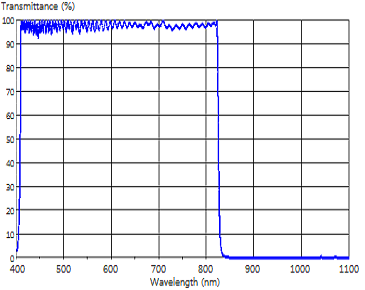

825nm OD4 Filter

|

|

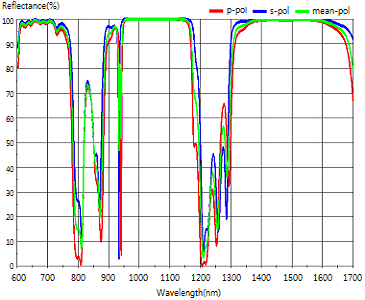

3W Laser HR Coating

|

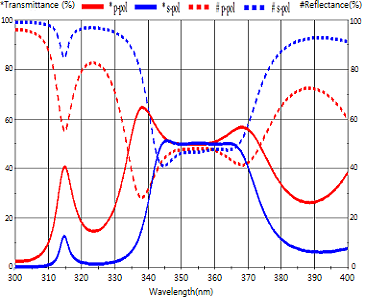

355nm NPBS (Plate)Coating

|

|

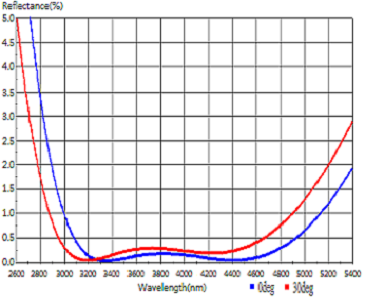

MWIR AR Coating [Ge/Si/Zns/ZnSe]

|

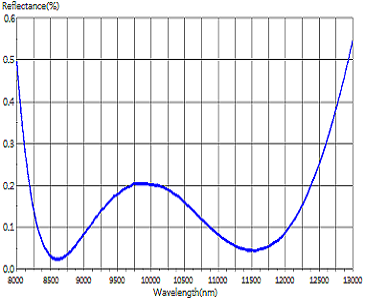

LWIR AR Coating [IRG26/Ge/Zns/ZnSe]

|

Coating Room

|

|

|

ALL MENU

ALL MENU